Laser welding

Laser welding offers enormous advantages. The precisely accurate processing reduces the heating of the surrounding material which implies a minimal heat distortion. Furthermore the weld seam can be adjusted in depth and amplitude. The alternatives of point-, seam- or circular seam welding offer multifunctional solutions for their connection task. And the combination of different materials creates the application for quite a wide spectrum.

The precise targeting of the laser weld seam leads to an almost artistic, aesthetic appearance of the finished result. A clear characteristic of highest precision and simultaneously a signet of quality for a secure connection.

Our LASERDEVICES

consists of modern equipment and machines from LASER TECHNIK

Laser marking

Marking with laser technology offers a wide range of options for signing and labeling.

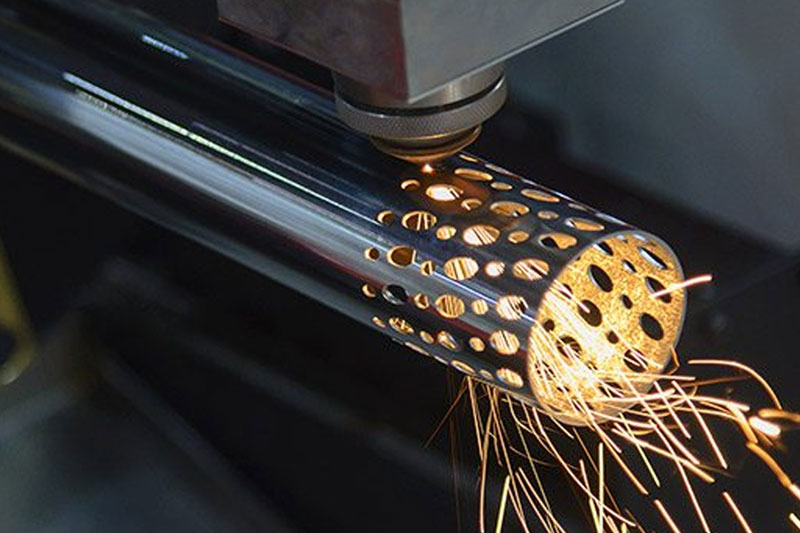

Laser cutting

Our laser cuts parts from different materials with an accuracy of up to +/- 0.005 mm.

read more

Laser drilling

We use three laser drilling processes to produce everything from micro-boreholes to large boreholes.

read more

Laser welding

Laser welding for precise processing and reduces heating of surrounding material.

read moreAs subcontractors, we produce components and assemblies for customers in almost all industrial sectors - from prototypes to small batch series.