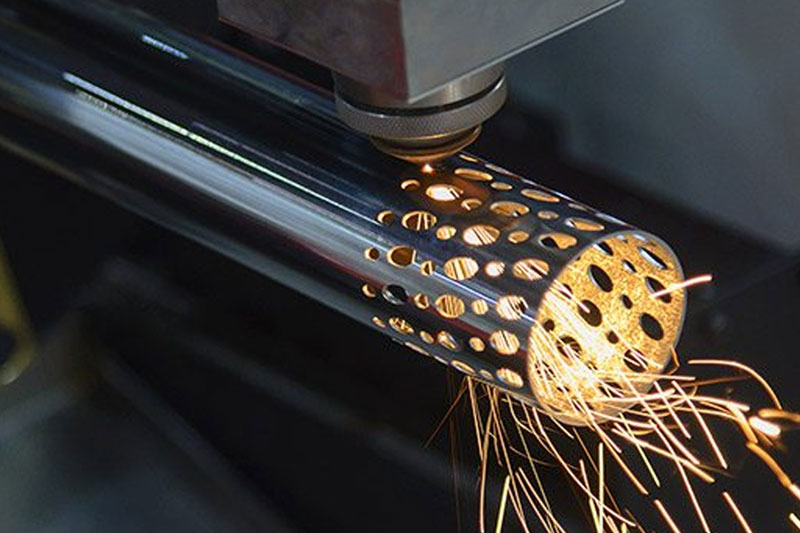

Highly dynamic and precise finish blanking with laser

endox laser technology is able to cut out parts from sheet metal or even out of foils with an accuracy of +/- 0.005 mm. Because of the highly dynamic rotation and swivel axis any tubes or cubic parts can be meticulously worked out.

Finish blanking is a process by which the width of the remaining bar is similar to or smaller than the material thickness. A further characteristic is a very small cutting gap dependent on material thickness (from 0.025 mm).

The exact construction and planning of the working processes ensures reliably in the production of the component.

Adjustment insert with a cut crack of 25 µm

Medical bone saw for the surgery. Application without regrinding.

Fast production of a stamping part prototype.

Contact foil for the keyboard of a mobile telephone.

Our LASERDEVICES

consists of modern equipment and machines from LASER TECHNIK

Laser marking

Marking with laser technology offers a wide range of options for signing and labeling.

Laser cutting

Our laser cuts parts from different materials with an accuracy of up to +/- 0.005 mm.

read more

Laser drilling

We use three laser drilling processes to produce everything from micro-boreholes to large boreholes.

read more

Laser welding

Laser welding for precise processing and reduces heating of surrounding material.

read moreAs subcontractors, we produce components and assemblies for customers in almost all industrial sectors - from prototypes to small batch series.